The Side Seam Tape for Maximum Product Safety

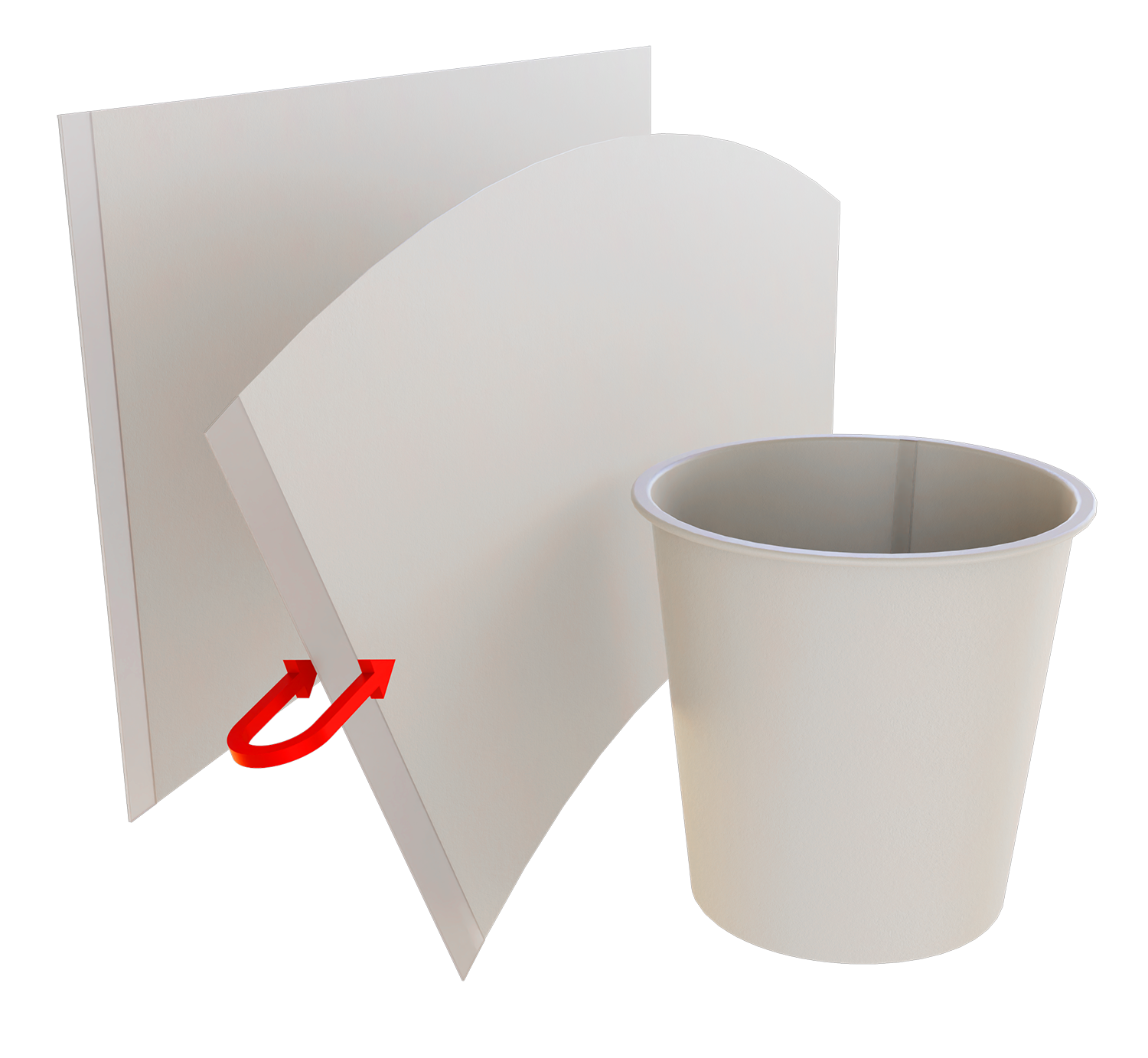

To increase the durability and tightness of cups and containers, HÖRAUF offers the option of applying a side seam stape that covers the open cut edge of the packaging.

For Dairy Packaging

In dairy applications, the primary purpose of the side seam tape is to prevent the wet product from coming into contact with the exposed paper edge and penetrating the cut surface. The side seam tape provides optimal protection for both packaging and product, ensuring consistent high quality throughout the entire shelf life.

For Hermetic Cups and Containers

Beyond protecting the cut edge from internal influences, the side seam tape also creates an additional barrier against external factors such as oxygen. This makes the tape essential for producing premium cups and straight-walled containers that require hermetic sealing—such as those used for food, coffee or tobacco packaging.

With HÖRAUF’s advanced forming and sealing technology, the machines meet the highest requirements in terms of quality and tightness. The side seam tape application plays a central role in achieving these standards. Coffee, tobacco, liquid products, and other high-value goods benefit from this enhanced barrier layer, which preserves flavour, freshness, and product quality for a long shelf-life..

Inline or Offline – Maximum Flexibility

The side seam tape be applied inline directly in the cup-forming BMP and container forming CFM machines or offline using a dedicated unit (DSA 100). This gives manufacturers maximum process reliability and full operational flexibility.

NEW: BMP 200 –

with Side seam Tape and Rim Flattening at 200 cycles/min.

The new BMP 200 Universal cup-forming machine is now capable of producing cups with side seam Tapes at 200 cycles per minute inline. The integrated applicator has been upgraded and further optimized. This gives users maximum flexibility to efficiently produce both drinking cups and hermetically sealed high-barrier containers with flatterned rim.